Why Valve Solutions

Valve Solutions, LLC (VSI), established in 1995 in Alpharetta, GA, is a premier manufacturer of valves and actuators for both commercial and industrial markets. VSI also specializes in delivering automated valve packages to some of the world’s largest controls companies. Its sister company, VSI Waterworks, caters to the municipal markets with AWWA-certified valves.

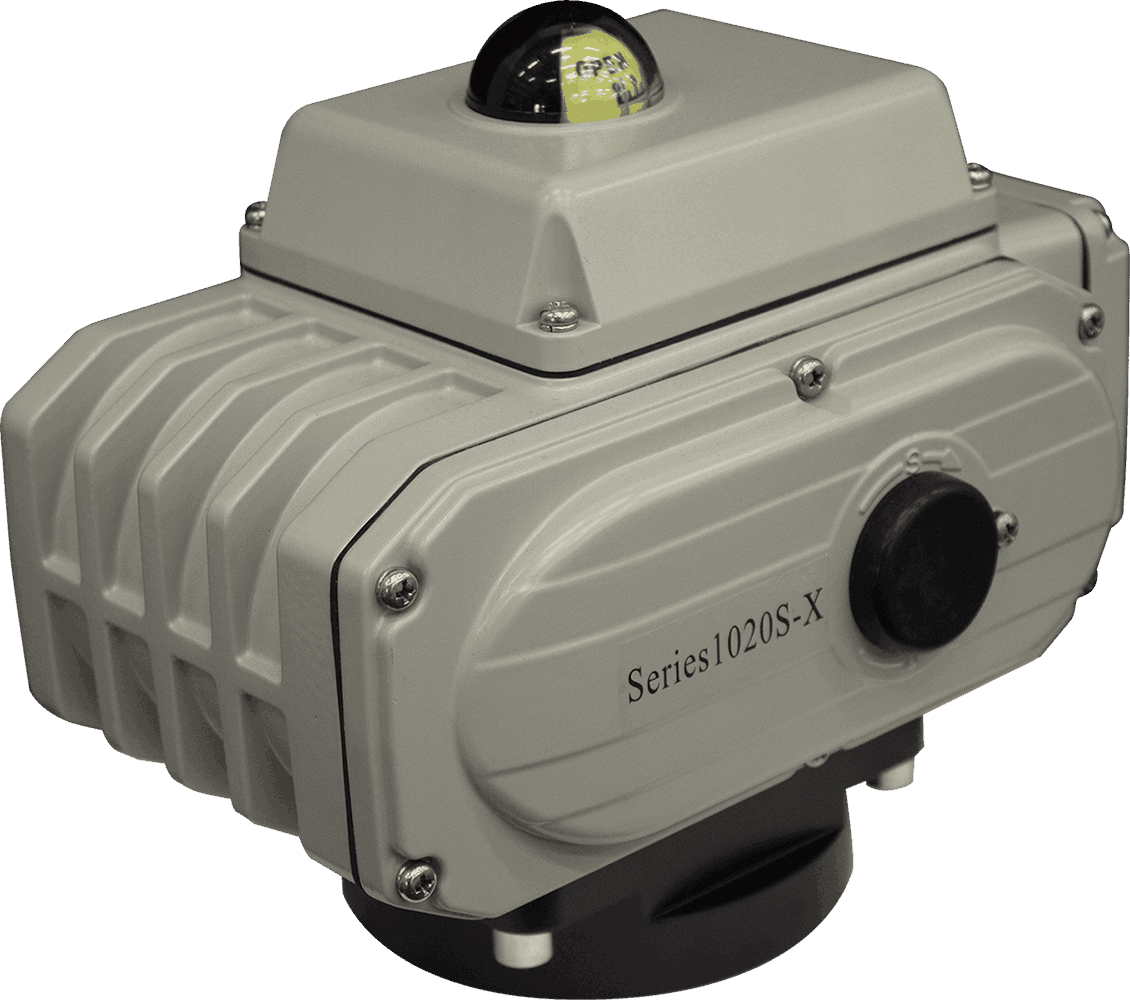

VSI initially entered the market by selling automated ball valve packages as an authorized OEM of Apollo ball valves and Siemens open-air damper actuators. In May 2000, VSI expanded its product offerings with the launch of the Series 2000 Resilient Seated Butterfly Valve and the Series 1000 Electric Actuator. These new product lines were complemented by partnerships with leading HVAC valve and actuator suppliers, including Belimo, Siemens, Johnson Controls, and Honeywell.

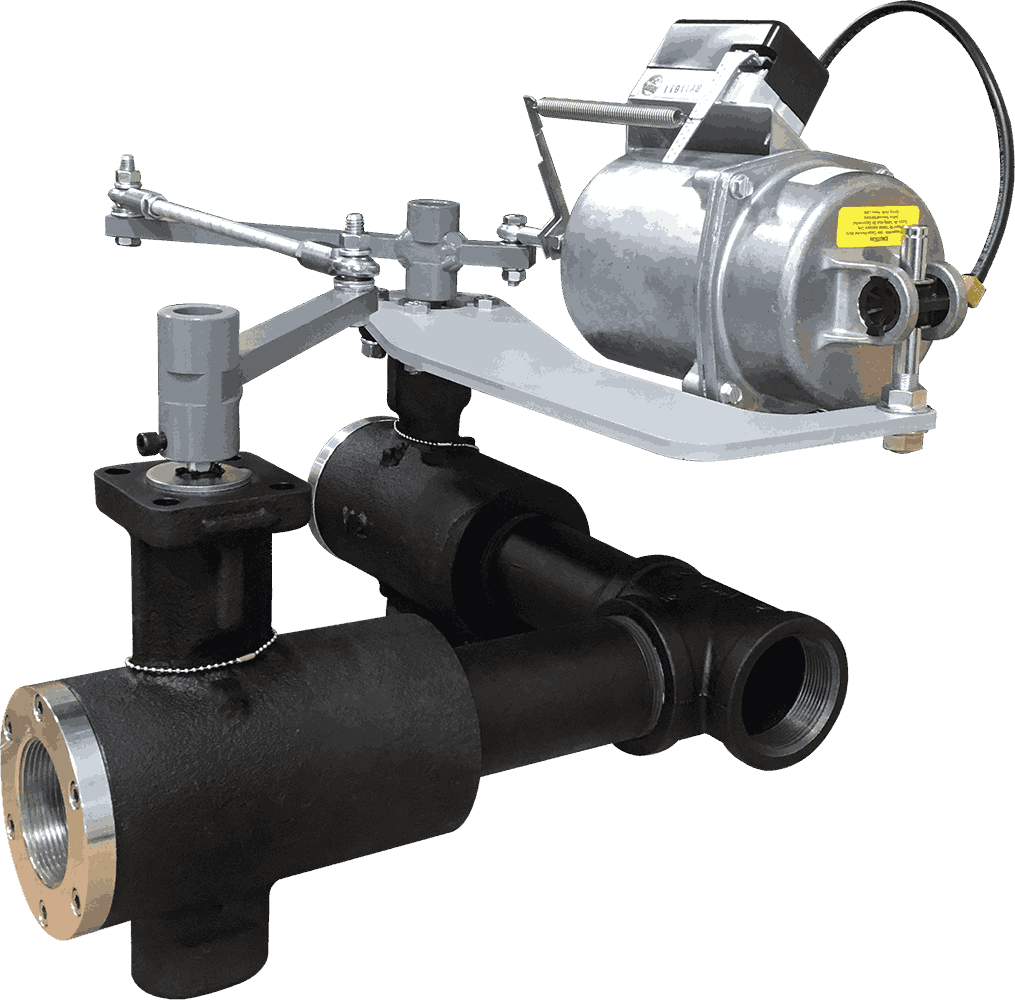

In 2002, VSI introduced its flagship product, the Series V High Performance Segmented Ball Valve. This innovative valve offers a superior and cost-effective alternative to traditional globe valves for flow control in hydronic and steam systems. The Series V has been widely recognized, including features in ASHRAE journals, and has received positive feedback from customers for its performance.

Continuing its commitment to innovation, VSI rebranded and launched several new products in 2012, including the Series 2100 Resilient Seated Butterfly Valve, the Series 1000-X Electric Actuator, and the Series C Pneumatic Actuator, all designed with ISO patterns for direct mount packages. This eliminates the need for costly linkages, further enhancing efficiency and reducing costs for clients.

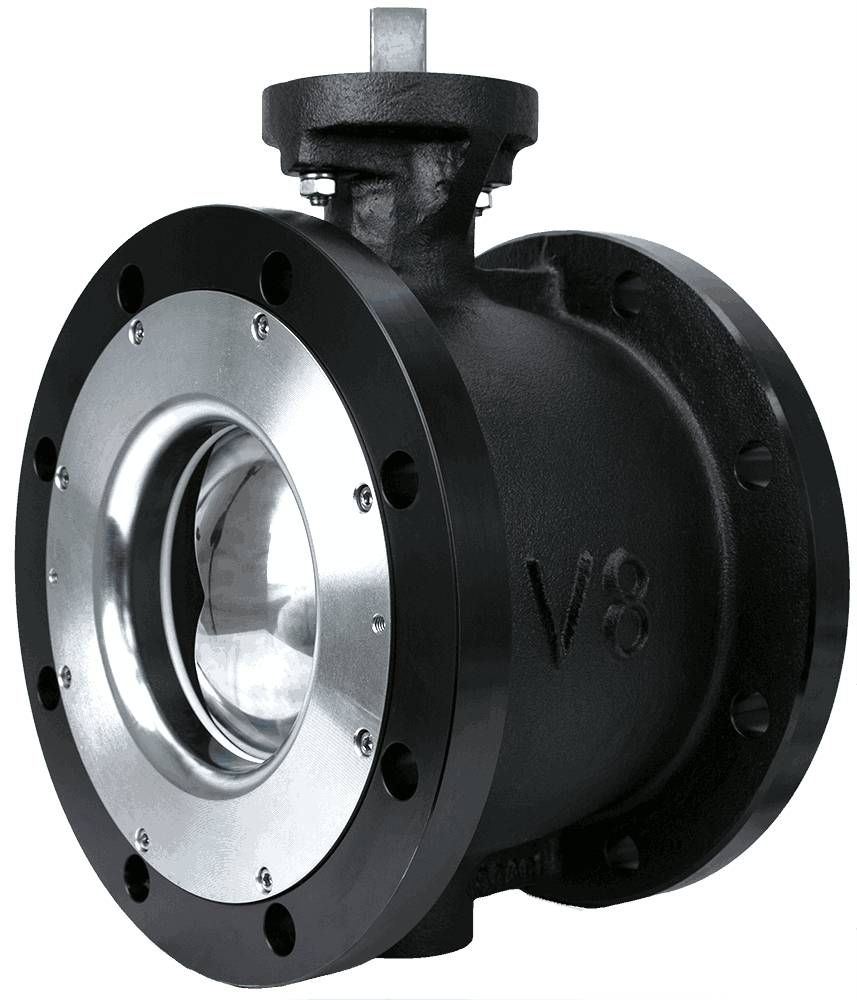

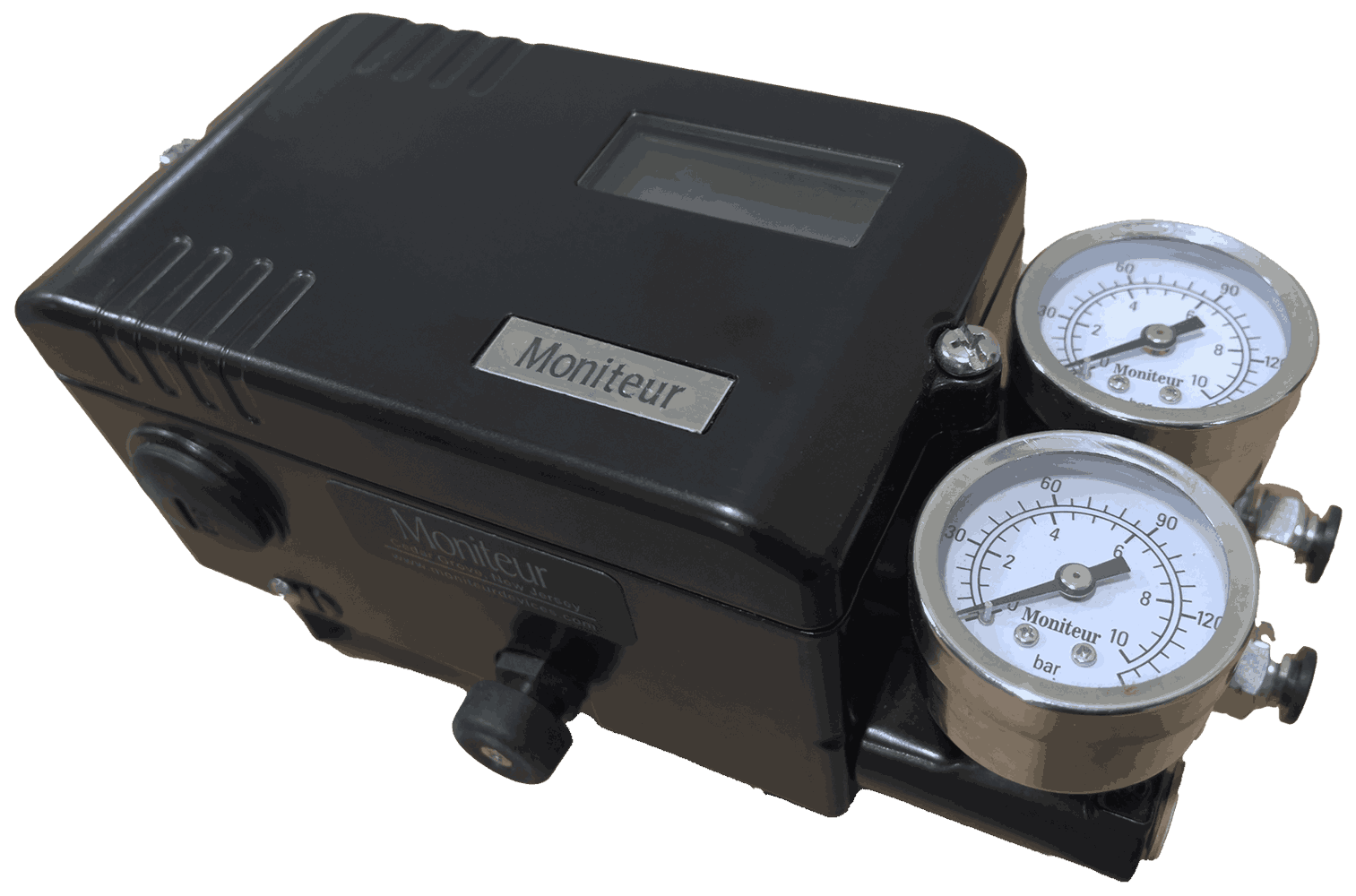

VSI’s partnerships have expanded to include industry leaders such as Sharpe Valves, ABZ Valves, and Moniteur Devices. For customized valve solutions tailored to specific needs, VSI remains a trusted partner in the industry.